GD1 RFID Application in Supply Chain Management

The unprecedented disruptions brought by COVID 19 pandemic has greatly impacted the global supply chain, mankind industrial activities brought to a halt due to shortages of materials, lack of healthy labor force and strict SOP compliance. In the context of Malaysia, one of the greatest impacts is the acute labor shortage whereby the usual pre-pandemic era foreign labor supplies has disappeared due to the border locked down. This forces the manufacturers and traders to resort to other means and this has led to the soaring demand for automation. While large able manufacturer whom has well planned processes and financial means can be readily convert to automation, most SME lingers on with less or no option available.

For these SMEs, one of the way to reduce the dependencies of man-power would be to relook at the warehouse operations which can be easily convert to a system driven process. One such approach is to introduce the proper warehouse management to allow for stock location management, optimization, FIFO to reduce wastages and allows greater visibilities. For SMEs whom has already adopted Auto-ID technologies such as barcode system can enjoy greater efficiencies by adopting RFID technologies. RFID allows auto detection and counting of items, increase accuracies of inventory management by automating stock in and out location by using RFID enabled forklift. Pallets with RFID can be tracked and location can be determined from system.

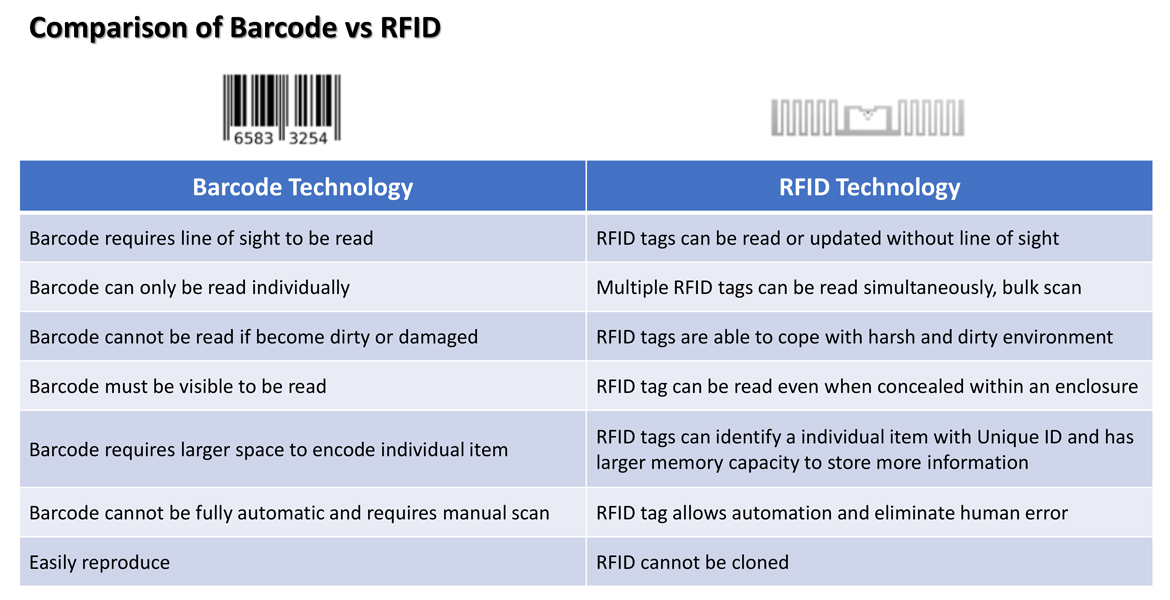

RFID or Radio Frequencies Identification is a technologies where a electronics chip with Electronics Product Code ( EPC ) can be read by a scanner that is located 3-5 meter away. The technologies allows mass scanning of items on the pallet in on go as compare to barcode. Table below shows the difference between RFID and Barcode.

RFID technologies was invented in the mid of the 20th century and over the decades, the technologies has evolved into many applications and comes in different form factors. For example the passport we hold, the credit card we used are having RFID technologies embedded within. In the context of supply chain and warehousing application, RFID technologies are usually in the form of Label with embedded chip, a rubber like tag attached the pallet. Below diagram shows the family of different RFID technologies tag.

GD Innovations, a strategic alliance partner of GS1 Malaysia has more then 10 years of experience in implementing RFID technologies to warehouse, supply chain track and trace provides turnkey solution (software and hardware) and advisory to SMEs whom are interested to convert, upscale their current warehouse system to RFID. Please feel free contact us for your needs!