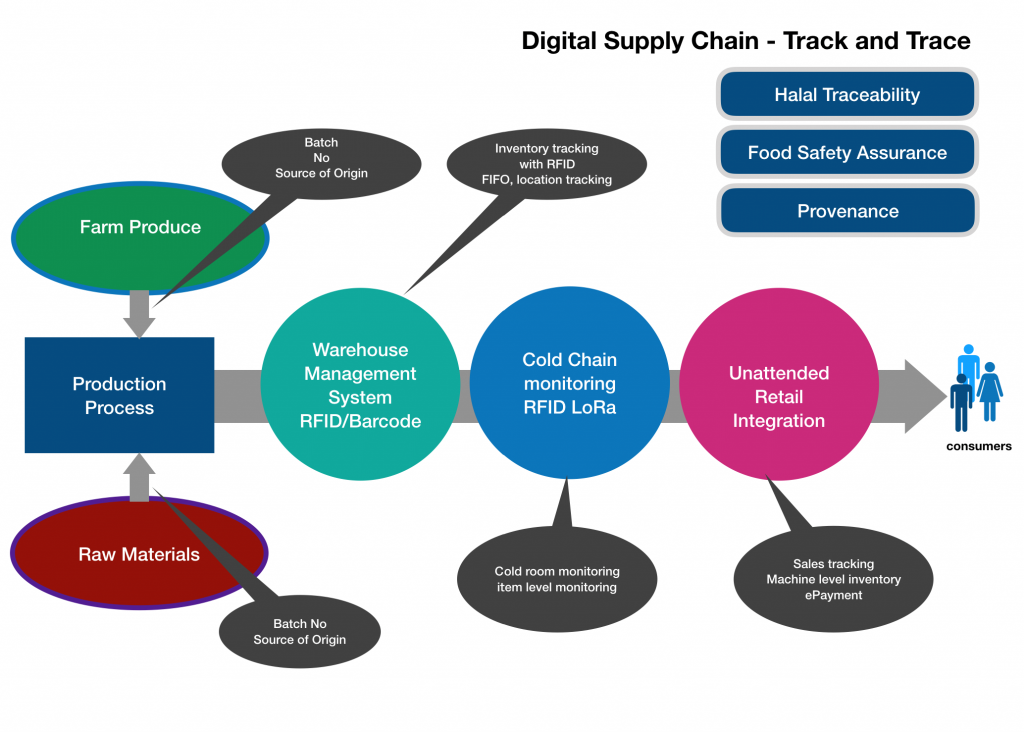

In the current borderless world, goods and raw materials are shipped from different region across the globe, resulting in a complex and entangled global supply chain.

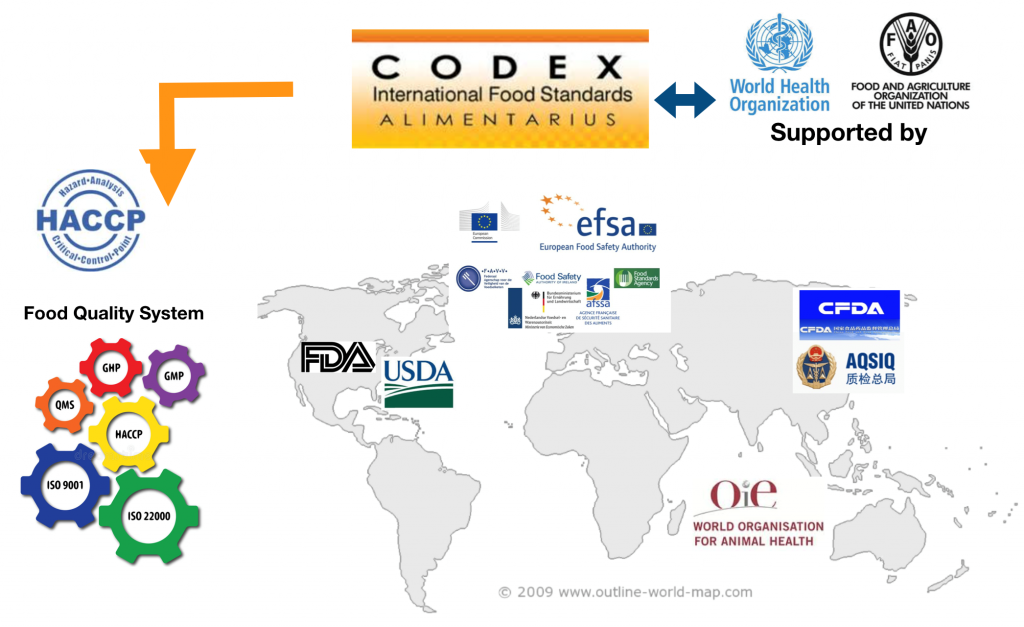

The complexity in our global supply chain is further complicated with the various rules and regulations put in place by global, regional or national custom agencies to ensure food safety, halal assurance as well as to counter illegal trade and smuggling activities.

Global regulatory agency such as CODEX Alimentarius, World Health Organization, World Organization for Animal Health (OIE) , Federal Drug Agencies ( FDA) and alike has established standard operating procedures (SOP ) and mechanism to regulate the movement of goods and raw materials in their respective jurisdiction.

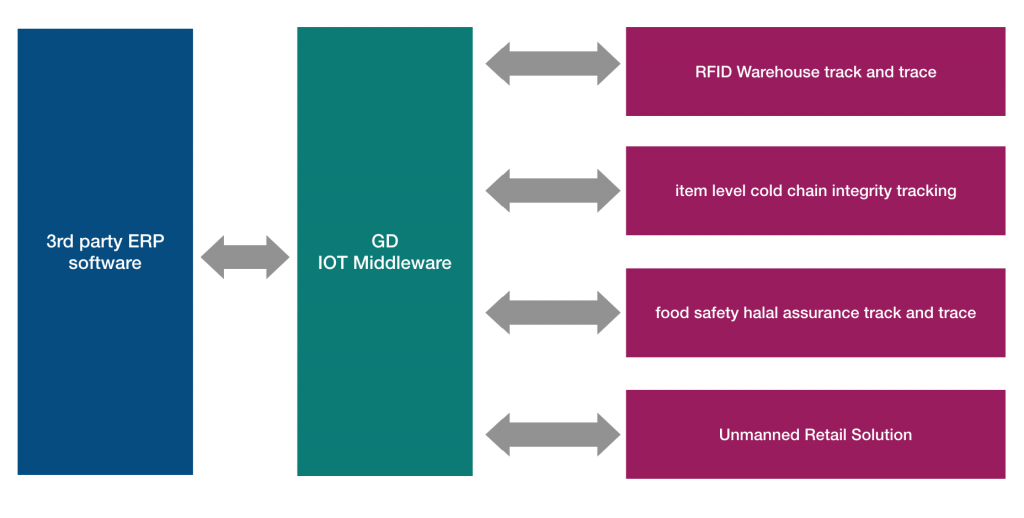

GS1, a Global Non Profit Organization has been the pioneer in developing and maintaining standards including barcodes and promoting global trade business language system with its Electronic Product Code (EPC) as well as the the usage of RFID and barcode as the Auto ID technologies in bringing speed and accuracies to the data capturing. This real time data can be further share using a central data repository mechanism known as EPCIS which allows information exchange among different trading parties, entities across supply chains bringing further transparency in the goods movement and facilitate a thriving cross border trading. GD Innovations is currently a GS1 Malaysia strategic partner in promoting EPC and EPCIS based best practies and RFID track and trace solution for Malaysia manufacturers and exporter.